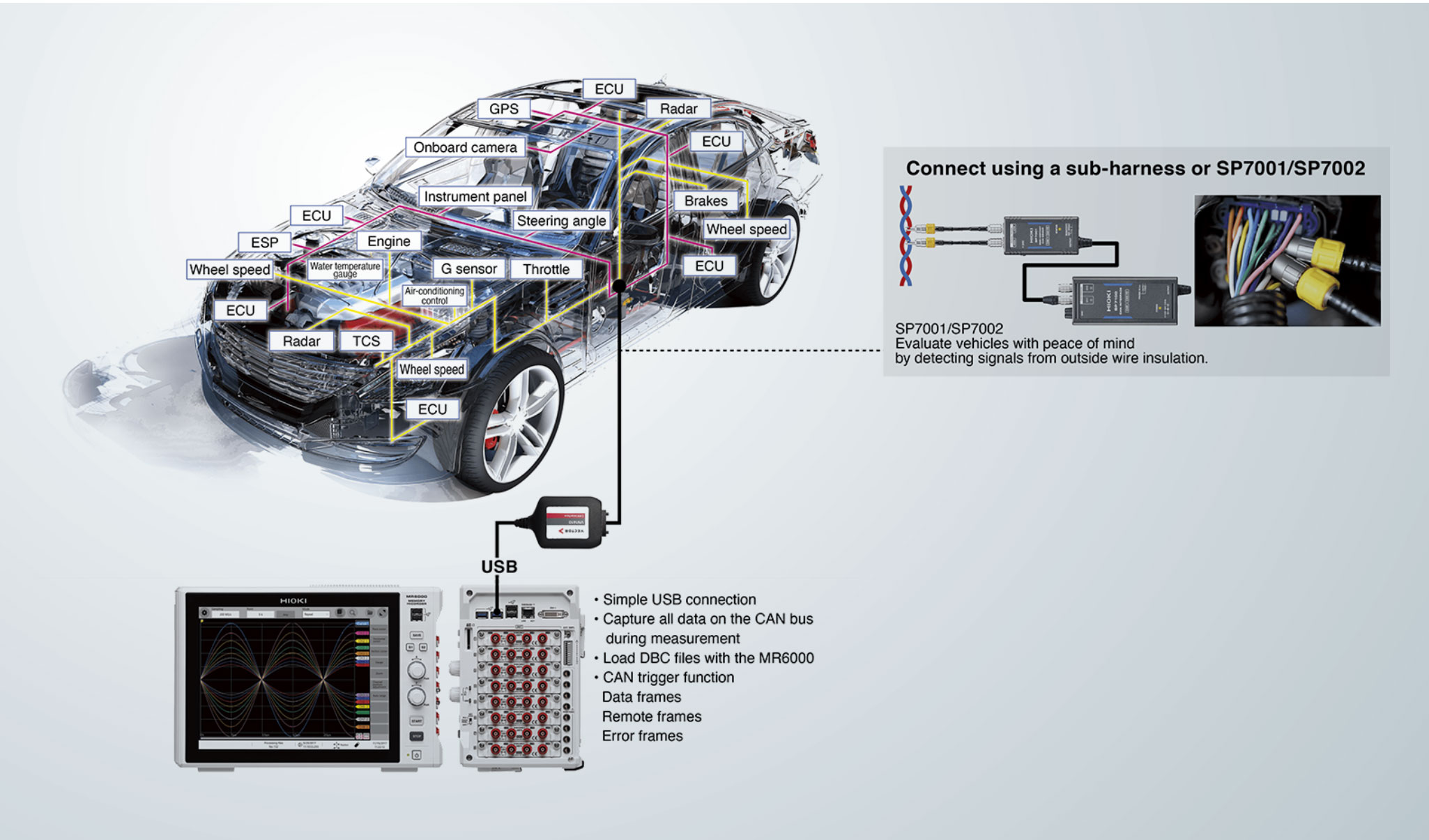

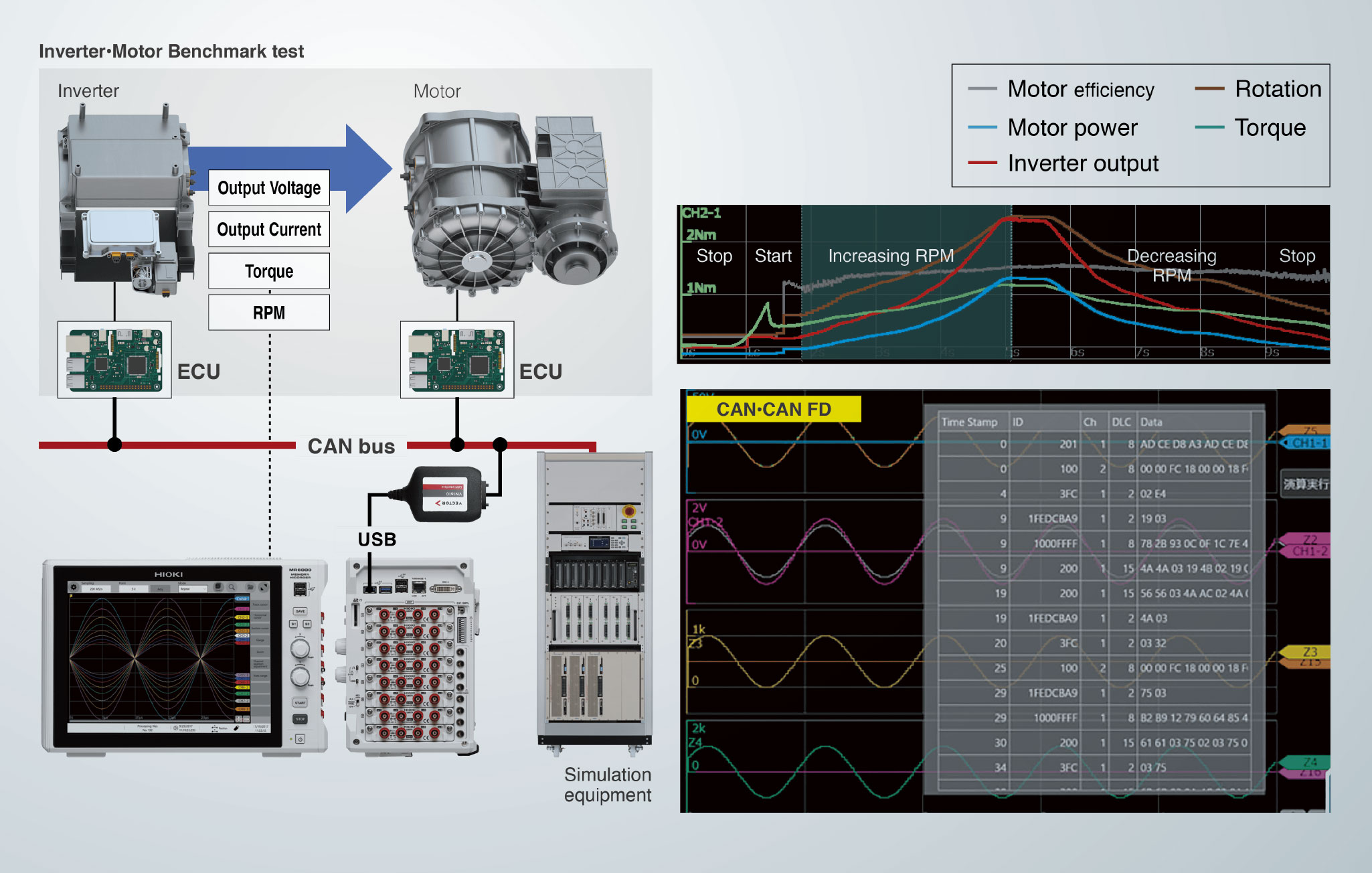

Accurately assess behavior during HILS testing and vehicle evaluation by simultaneously measuring control and sensor data on the CAN bus and actual analog values.

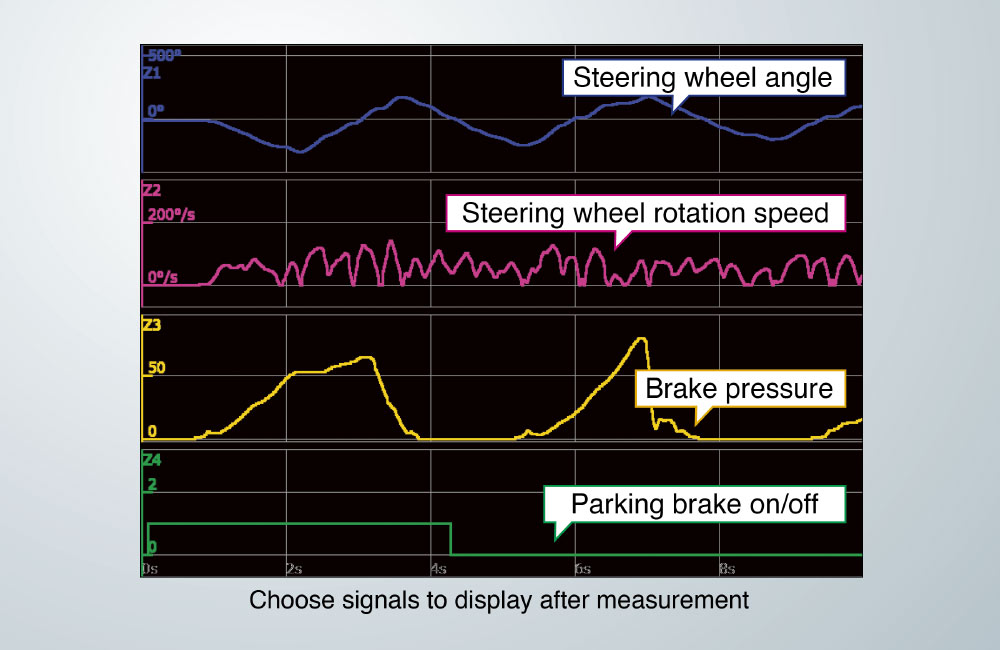

Vehicle evaluation

When dealing with parameters that are difficult to measure in assembled vehicles, you can use data on the CAN bus to assess vehicle condition and status. Use the Non-Contact CAN Sensor SP7001/SP7002 to monitor a CAN bus without the need for bothersome preparations like fabricating sub-harnesses or modifying cables. Simply remove the sensors when you’re finished, without any effect on the vehicle.

In HILS evaluation, a simulation system reproduces CAN signals and other parameters based on the situation being simulated. The motor or inverter is controlled while assessing the condition of its ECU based on CAN data. Motor characteristics and efficiency can be calculated under a variety of anticipated conditions by capturing CAN signals along with data such as inverter output voltage and current, torque, and frequency.

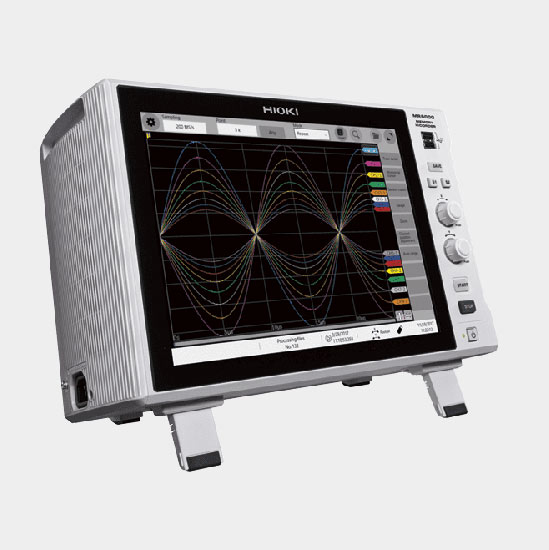

Memory HiCorder MR6000/MR6000-01

Non contact CAN Sensor SP7001/SP7002

4CH Analog unit

U8978

3CH Current unit

U8977

Freq unit

U8970

Strain unit

U8969

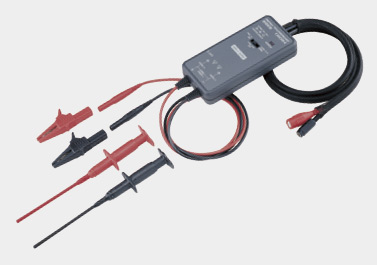

Differential probe

9322

AC/DC Current probe

CT6841-05

Connection cord

L919

Torque sensor* (strain gage-type converter)

(For more information about the sensor, please contact the sensor manufacturer.)

Demo Video

Vehicle CAN bus monitoring

Do you have any questions or a specific inquiry? We are ready to find your measurement solution.

Please send us a message to our contact email address or contact a HIOKI partner in your country.